The addition of the SPATZ+ CoboFeed to Matuschek's ServoSPATZ+ welding systems opens up completely new possibilities in line architecture. In automated series production, the SPATZ+ CoboFeed is used to feed e.g.

to weld them directly in the body or in the component. This allows production lines with great savings potential to be realized.

To weld nuts or bolts in the body, the corresponding components previously had to be fed to a stationary projection welding system in a separate process step. With the CoboFeed, this can be done directly in the car body in parallel with other process steps, such as spot welding!

One challenge in automotive joining technology is the joining of different materials, especially aluminum with steel.

With the SPATZ+ aluminum complete system, consisting of control, CapClean, as well as servo gun and CoboFeed, all joining variants, Al-Al, steel-steel with spot welding, as well as Al-steel with rivet welding, can be carried out in one process sequence!

In addition to the classic spot welded joints, aluminum is also joined to steel in a process-safe manner with the aid of weld rivets fed by CoboFeed.

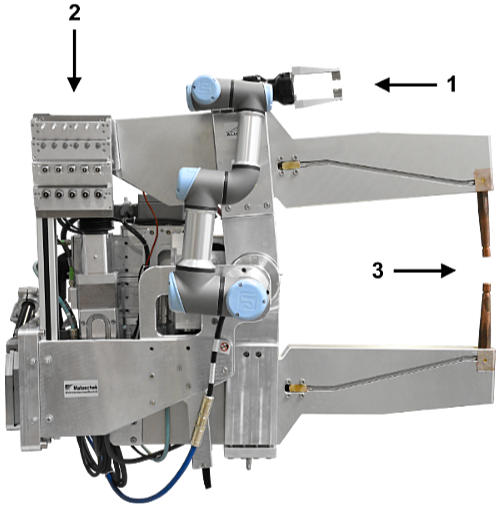

For this purpose, during the approach of the tongs, the gripper of the CoboFeed(1) removes the rivets from the magazine(2) and positions them on the component between the electrodes(3) for welding.

This can be done in any position in the room. After the welding processes in the component, the CoboFeed automatically refills its magazine from a filling station.