SPATZ+LSK – 专为精密电阻焊接而设计的精密电阻焊机头:

以下为 SPATZ+LSK 精密电阻焊机头的技术参数:

| 接触速度: | 5 - 20 mm/s (0.2 - 0.8 "/s) |

| 定位精度: | 1 µm (SPATZ+LSK80: 0.1 µm) |

| 最大运行速度: | 800 mm/s (31.5 "/s) |

| 最大行程: | 25 mm (1.0 "), (SPATZ+LSK300: 50 mm (2.0 ")) |

| 最大加速度: | 200 m/s² (656 ft/s²) |

| 最大时钟频率: | 4/s (取决于应用程序) |

| 马达电压: | 24 V |

| 特色: | 压力控制, 位置控制和部件识别 |

接触速度:

5 - 20 mm/s (0.2 - 0.8 "/s)

定位精度:

1 µm (SPATZ+LSK80: 0.1 µm)

最大运行速度:

800 mm/s (31.5 "/s)

最大行程:

25 mm (1.0 "), (SPATZ+LSK300: 50 mm (2.0 "))

最大加速度:

200 m/s² (656 ft/s²)

最大时钟频率:

4/s (取决于应用程序)

马达电压:

24 V

特色:

压力控制, 位置控制和部件识别

与 SPATZ+ 伺服焊接系统相配合,马图塞克制造了专为高焊接压力和高焊接电流应用而设计的焊接机头。

| 行程: | 180 mm (7.09") |

| 主轴螺距: | 10 mm (0.39") |

| 最大压力: | 10000 N |

| 最大速度: | 500 mm/s (19.69"/s) |

| 重量: | 15.7 kg (34.61 lbs) |

| 抱闸: | 是 |

| 位置测量单元: | 编码器 |

| 内置压力检测: | 是 |

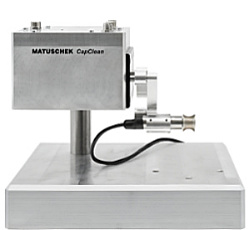

During resistance welding, the electrodes wear out and need to be cleaned or replaced regularly. Furthermore, different surface geometries are required for different welding tasks.

For example, a crowned and roughened electrode surface is essential for welding aluminum foils.

With the CapClean, different geometries and roughnesses can be selected using different grinding wheels and settings in the software.

The CapClean cleans and reforms the electrodes in a single work step and has been designed for fully automated systems. It can also be used at manual workstations or in the laboratory.