The SPATZ+LSK welding heads and pincers with electro-magnetic linear drive are designed for precision applications. SPATZ+LSK heads can be utilized as single heads, combined as a gap welding system or electrically floating pincers. It's state of the art concept and design has several advantages compared to pneumatic weld heads. Such as:

The technical advantages of the SPATZ+LSK micro welding heads and pincers are particularly resulting from the electro-magnetic linear drive. Perfect electrode follow-up characteristics, comparable with the follow-up performance of an ideal mechanical spring also improve weld quality. Self-locking behaviour due to friction which is typical for ball screw spindle systems is avoided. In addition, the linear drive requires no viscosity-varying lubricants. Despite the availability of high electrode force, the linear head is operated with safe 24 V DC motor power. Fields of utilisation are cycle time optimised, high speed automated production as well as challenging manual applications.

Unique and state of the art motion algorithms provide a soft touch down capability despite extremely fast positioning and force build-up. Even sensitive electrodes are prevented from damage without the need for a shock-absorber. Force change "on the fly" allows an changing of the electrode force within one weld program. The 25 - 50 mm (1.0 - 2.0 in.) stroke range simplifies the integration into welding machines. Operations are possible from any position within the traversing range. Highly precise electrode position and speed is guaranteed. An auto position referencing feature (REL and ABS) simplifies the electrode adjustment and increases the spot welds quality.

The SPATZ+LSK micro welding guns can be utilized as single servo

heads, combined as a gap system or electrically floating pincers.

The SPATZ+LSK includes a position measuring system with a resolution of 1 µm as standard. On automatic welding machines, this provides a cost-effective system for implementing a component and electrode wear detection. Also precise programming of electrode within a wide range can be done. The current can be terminated at any time by a position-controlled current switch-off. The travel cut-off allows to keep a fix position during the hold time resulting in consistent welds.

Available inverter power sources are SPATZ+H9000 and SPATZ+P500. The set-up of the SPATZ+LSK is carried out via SPATZStudio or via SPATZStudioNET PC-Software. The waveforms of the process signals (last weld) and the measured values of the last 10,000 welds are also available. Extremely short weld times are possible for micro-welding applications (e.g. less than 5 ms) including time increments of 0.1 ms. The precise internal position measuring system of the SPATZ+LSK series and the responsive control provided by the SPATZ+H9000 and SPATZ+P500 power sources ensures excellent and highly reproducible spot welds.

The following additional features characterize the SPATZ+LSK servo precision heads:

| Touchdown speed: | 5 - 20 mm/s (0.2 - 0.8 "/s) |

| Positioning accuracy: | 1 µm (SPATZ+LSK80: 0.1 µm) |

| Max. travel speed: | 800 mm/s (31.5 "/s) |

| Max. opening stroke: | 25 mm (1.0 "), (SPATZ+LSK300: 50 mm (2.0 ")) |

| Max. acceleration: | 200 m/s² (656 ft/s²) |

| Max. clock rate: | 4/s (depending on the application) |

| Motor voltage: | 24 V |

| Particularities: | Force control, position control and component recognition |

Touchdown speed:

5 - 20 mm/s (0.2 - 0.8 "/s)

Positioning accuracy:

1 µm (SPATZ+LSK80: 0.1 µm)

Max. travel speed:

800 mm/s (31.5 "/s)

Max. opening stroke:

25 mm (1.0 "), (SPATZ+LSK300: 50 mm (2.0 "))

Max. acceleration:

200 m/s² (656 ft/s²)

Max. clock rate:

4/s (depending on the application)

Motor voltage:

24 V

Particularities:

Force control, position control and component recognition

In conjunction with SPATZ+ servo welding systems, MATUSCHEK manufactures servo heads designed for higher forces and currents.

| Lift: | 180 mm (7.09") |

| Spindle pitch: | 10 mm (0.39") |

| Fmax: | 10 000 N |

| Traversing speed vmax: | 500 mm/s (19.69"/s) |

| Weight: | 15.7 kg (34.61 lbs) |

| Anti-twist security: | Yes |

| Position measuring unit: | Encoder |

| Internal force measurement: | Yes |

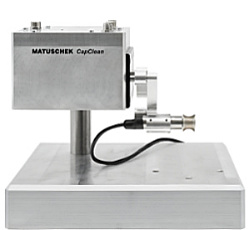

During resistance welding, the electrodes wear out and need to be cleaned or replaced regularly. Furthermore, different surface geometries are required for different welding tasks.

For example, a crowned and roughened electrode surface is essential for welding aluminum foils.

With the CapClean, different geometries and roughnesses can be selected using different grinding wheels and settings in the software.

The CapClean cleans and reforms the electrodes in a single work step and has been designed for fully automated systems. It can also be used at manual workstations or in the laboratory.

|

HIGH PRECISION WELD TIMER The SPATZ+LSK servo high precision welding heads are combined with SPATZ+ high precision weld timers. |

|

|

SERVO WELD TIMER The SPATZ+ servo heads are combined with SPATZ+ servo weld timers. |

|

|

SOFTWARE The entire setting, parameterization and visualization of the welding parameters is carried out by the SPATZ software family. |

|

|

SUPPORT, SALES AND TRAINING We would be happy to advise you on the selection of suitable solutions for your individual welding tasks and inform you about our training portfolio. |